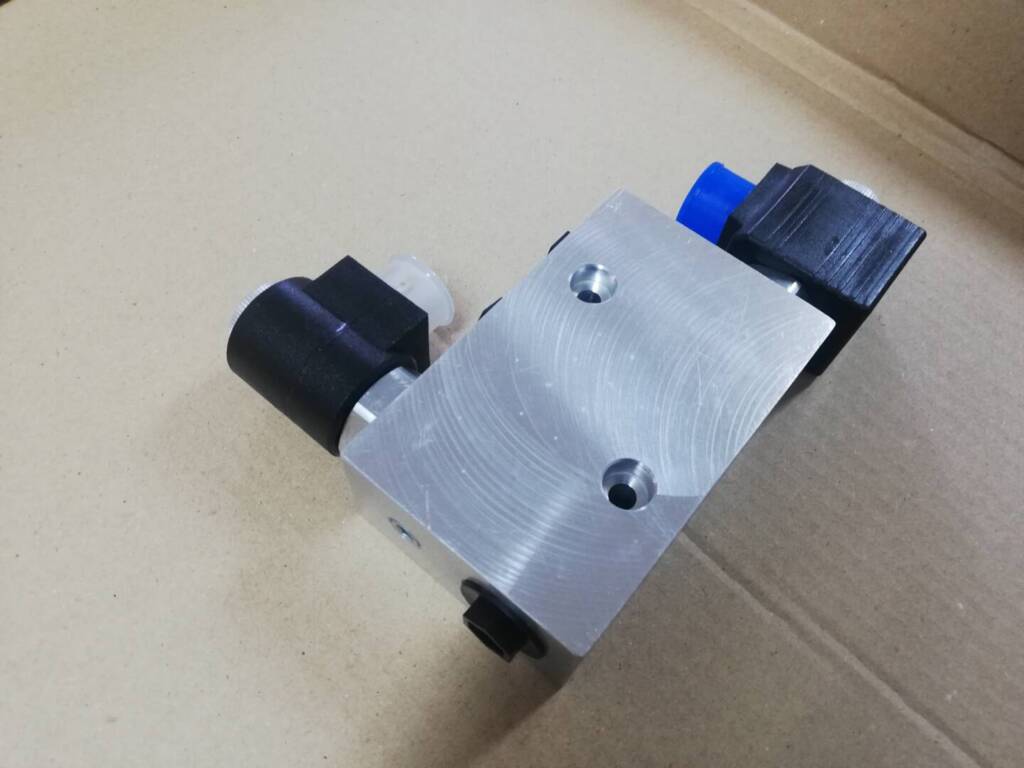

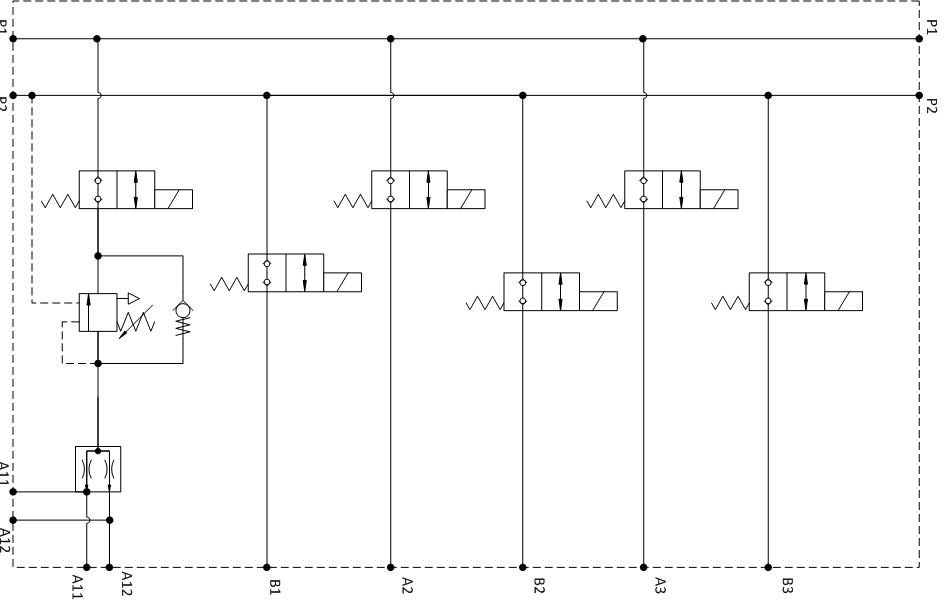

This particular valve was designed as an alternative to a previously existing solution to control a cylinder group, built out of pipe fittings and spool typo direction control valves. After working with the customer on the project, it became clear that the leakage losses, a known drawback of such direction control valves, can be avoided in this application if poppet valves are used instead. The whole system could be integrated in one manifold, which would significantly reduce the number of required parts in the final assembly. The ports of the manifold were designed to match the application and allow for easy connection to the hydraulic system of the machine. Our proposed solution not only simplified the assembly of the system but improved its operation as well.